Type:

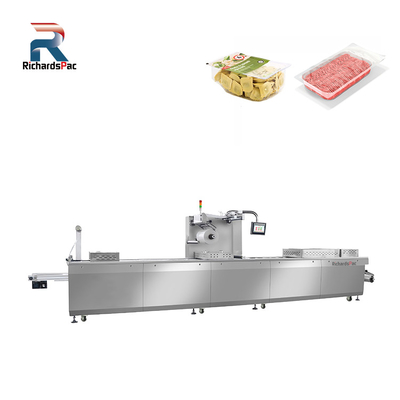

Multi-Function Packaging Machine

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Farms, Retail, Other

Weight (KG):

1800

Showroom Location:

Egypt, United States, Germany, Indonesia, Russia

Condition:

New

Function:

FILLING, Wrapping, Laminating, Sealing, BOXING, counting, Industry Packaging Sealing

Application:

Food, Beverage, Commodity, Medical, Machinery & Hardware, Textiles, Cigarettes

Packaging Type:

Barrel, Bags, Film

Packaging Material:

Plastic

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V/380V/460V 50HZ/60HZ

Dimension(L*W*H):

7000x1250x2100

Warranty:

1 Year

Key Selling Points:

Long Service Life

Marketing Type:

New Product 2022

Machinery Test Report:

Not Available

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Pump, PLC

Production Capacity:

20bag/min, 10bag/min

Product name:

Vacuum Packaging Machinery

Usage:

Food Vacuum Package

Keyword:

Automatic Vacuum Sealing Machine

Name:

Stretch Film Vacuum Packaging Machine

Chamber type:

Automatic Continuous

Model:

RS320/RS420/RS520

Packing machine:

Food Thermoforming Vacuum Packing Machine

Material:

SUS304 Food Grade Stainless Steel

Advantage:

High Efficiency

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!