Type:

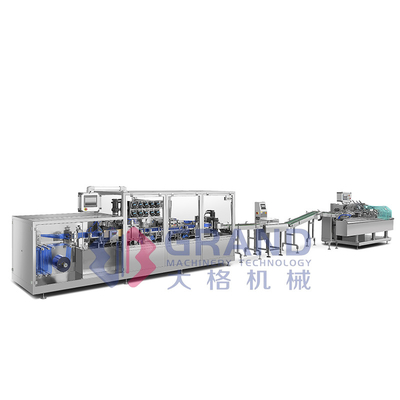

Multi-Function Packaging Machine

Applicable Industries:

Hotels, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Printing Shops, Food & Beverage Shops, Other, Pharmaceutical, hospitals, cosmetics agricultural

Weight (KG):

2000

Showroom Location:

Egypt, Turkey, Indonesia, India, Thailand

Condition:

New

Function:

FILLING, Wrapping, Labeling, Capping, Sealing, BOXING, Embossing, SLITTING, counting, packaging

Application:

Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, Cigarettes

Packaging Type:

Bottles, Film

Packaging Material:

Plastic

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220-380V

Dimension(L*W*H):

5200*1050*1800(mm)

Warranty:

1 Year

Key Selling Points:

Multifunctional

Marketing Type:

Hot Product 2022

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Pump, PLC

Production Capacity:

180-250times/Single cut

Product name:

Automatic Vertical Packing Machine

Usage:

Liquid Paste Jam Packing

Main Function:

Weighing Forming Filling Sealing

Filling material:

Liquid

Machine type:

Vertical Automatic Packing Machine

After-sales Service Provided:

Online Support

Film material:

PP PE

Packing Machine Function:

Automatic Filling Saeling

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!